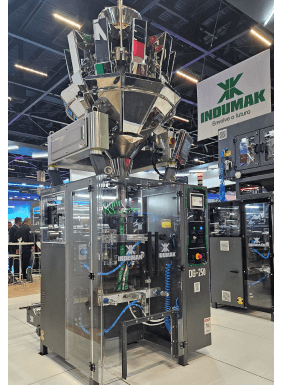

High-performance automatic packaging machine: precision, speed, and efficiency for the industry.

Robust solutions for industrial packaging across multiple sectors, from food to chemicals.

What is an automatic packaging machine?

It is equipment designed to place products into packages and seal them with precision and consistency.

This is an essential solution for industries seeking to optimize their packaging operations while reducing production time and increasing process reliability.

With automated packaging, it is possible to achieve fast and continuous cycles. This eliminates human error and ensures standardized and secure packages.

Understand the difference between automatic and manual packaging machines

Critério

Automatic Packaging Machine

Manual Packaging Machine

Precision and standardization of packages

✔ High precision and uniformity

✘ Low standardization, subject to human variations

Reduction of errors and waste

✔ Reduz significativamente erros e perdas

✘ Higher risk of failures and waste

Ergonomics and safety

✔ Automated operations with minimal physical effort

✘ Greater physical effort and ergonomic risks

Speed in production cycles

✔ High speed and consistency in production cycles

✘ Slower production and more prone to fatigue

Process control and traceability

✔ Possibility of integration with digital systems

✘ Manual control with lower traceability

Dependence on direct labor

✔ Reduced labor requirement, needs few operators

✘ High labor demand, directly dependent on workforce

Why invest in an automatic packaging machine?

By investing in a packaging machine, your industry achieves significant gains in performance, quality, and operational efficiency:

Reduction of operational costs

Increased productivity and efficiency

High-quality standards in packaging

Lower risk of contamination and human errors

Compliance with sanitary and safety regulations

With this solution, your brand stands out for its excellence and its ability to handle large volumes with maximum reliability, expanding its competitiveness in the market.

Automatic Packaging Machine Models for Different Needs

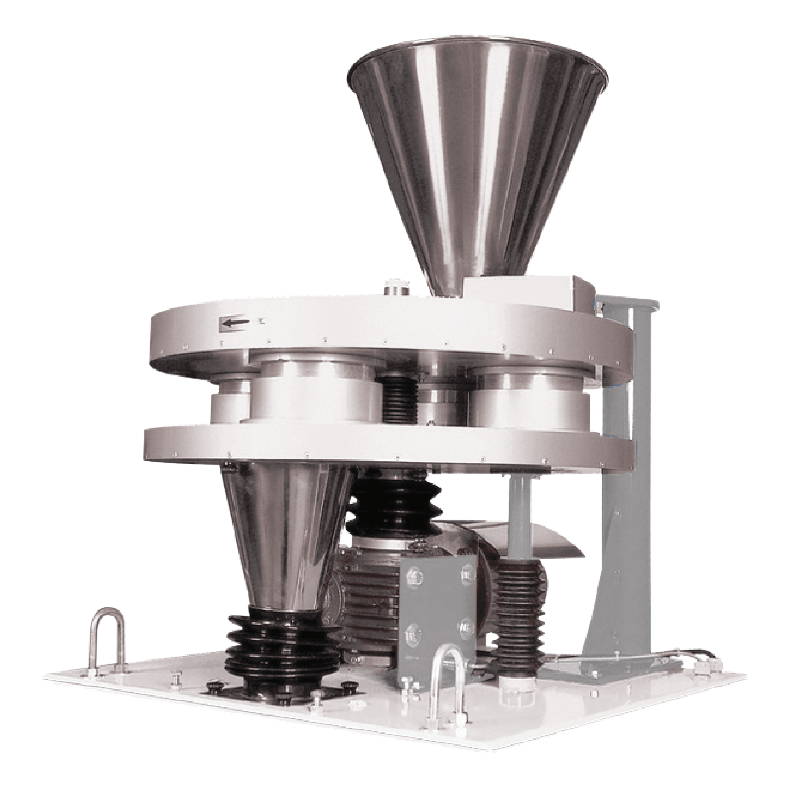

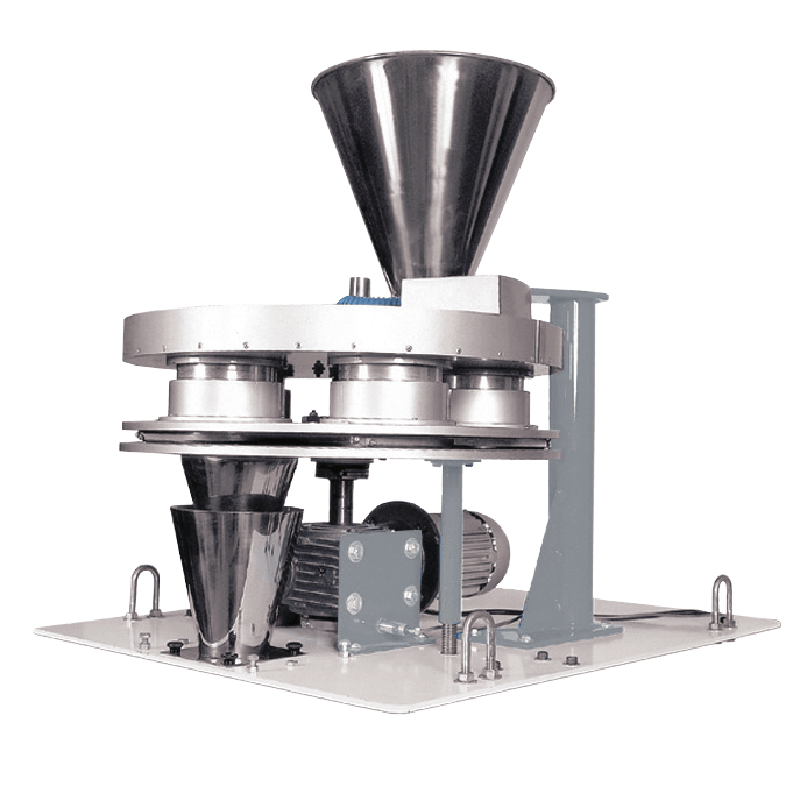

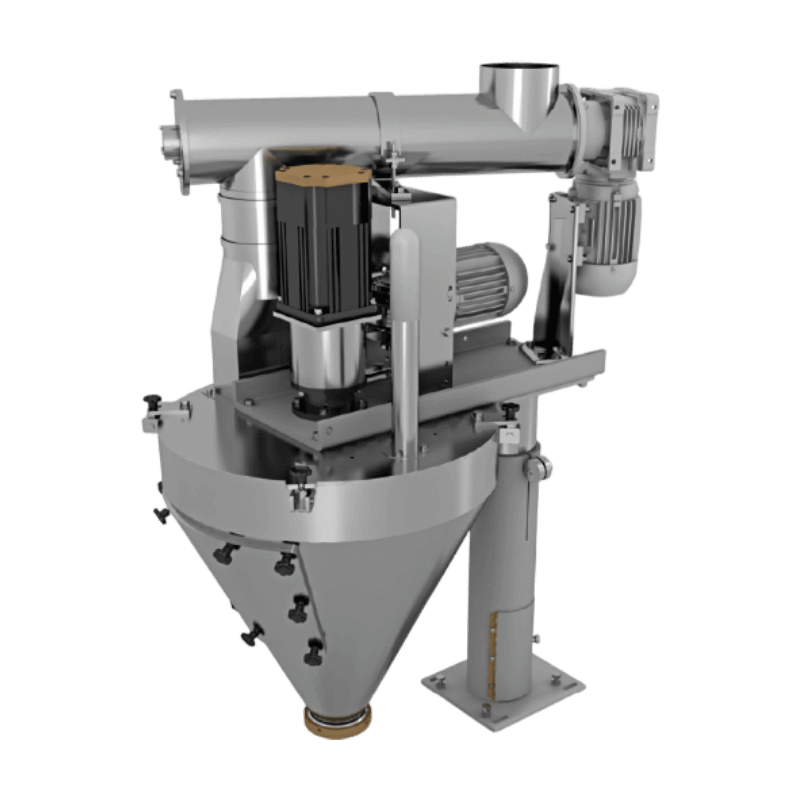

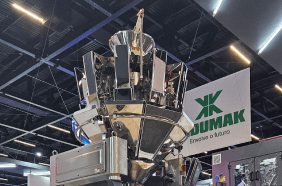

In the specialized segment, there are models of industrial packaging machines and dosing systems that offer the versatility required for a wide range of products and industries.

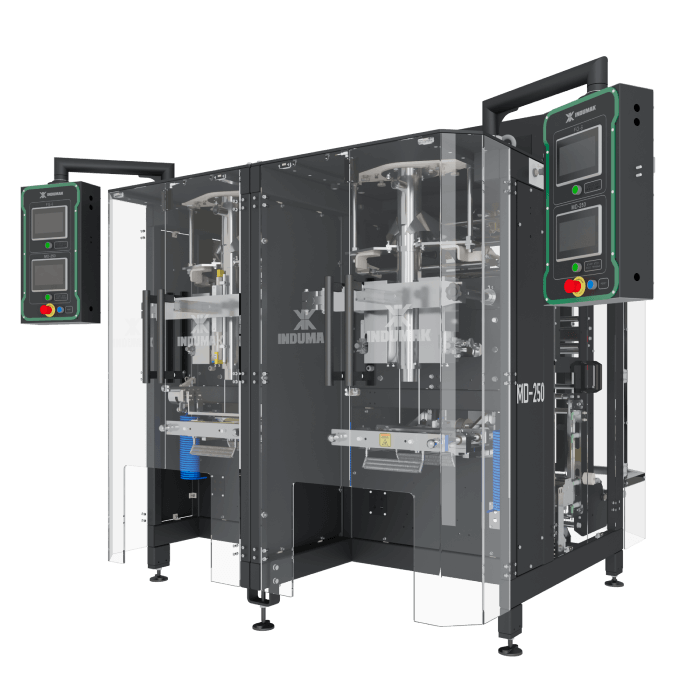

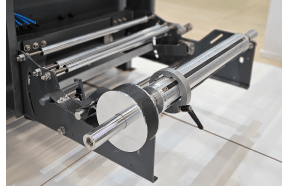

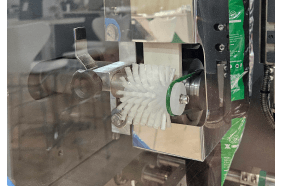

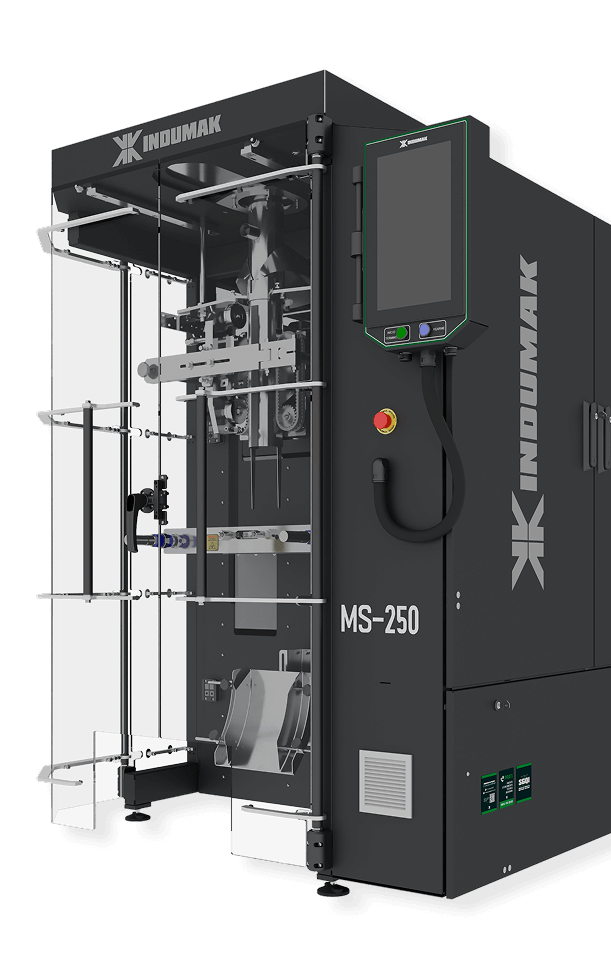

Packaging Machines

Equipment designed to package products in order to meet market demands.

They deliver excellent performance, help prevent product loss, and provide a modern appearance to the final package. They offer high versatility.

Indumak Models

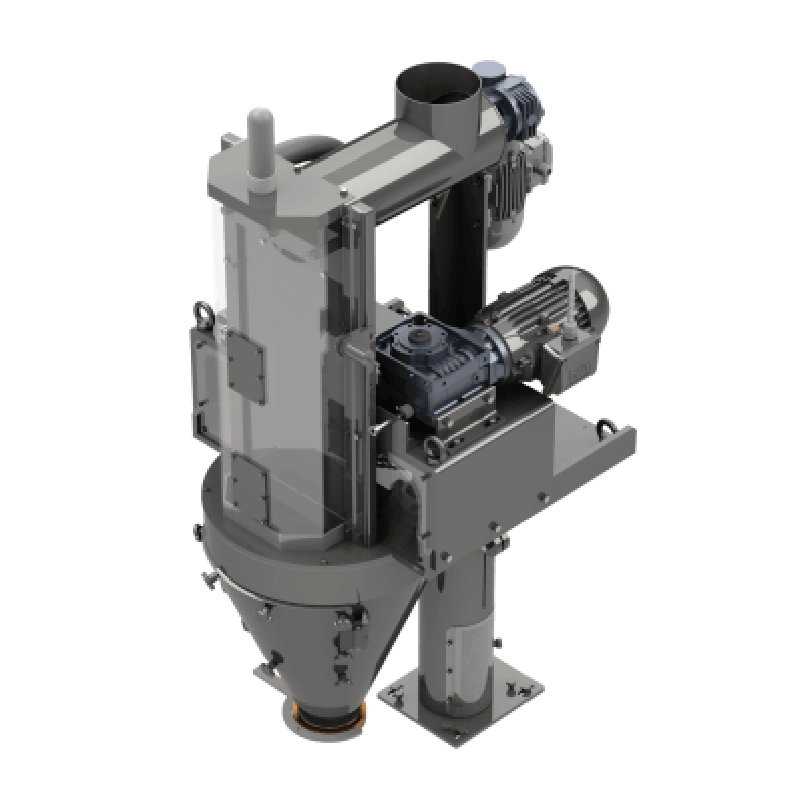

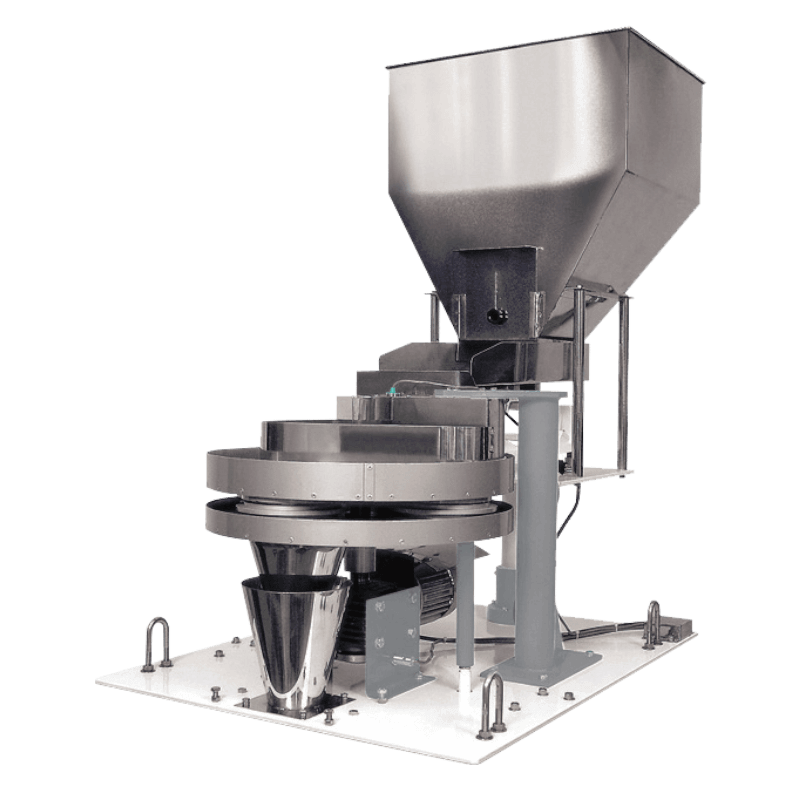

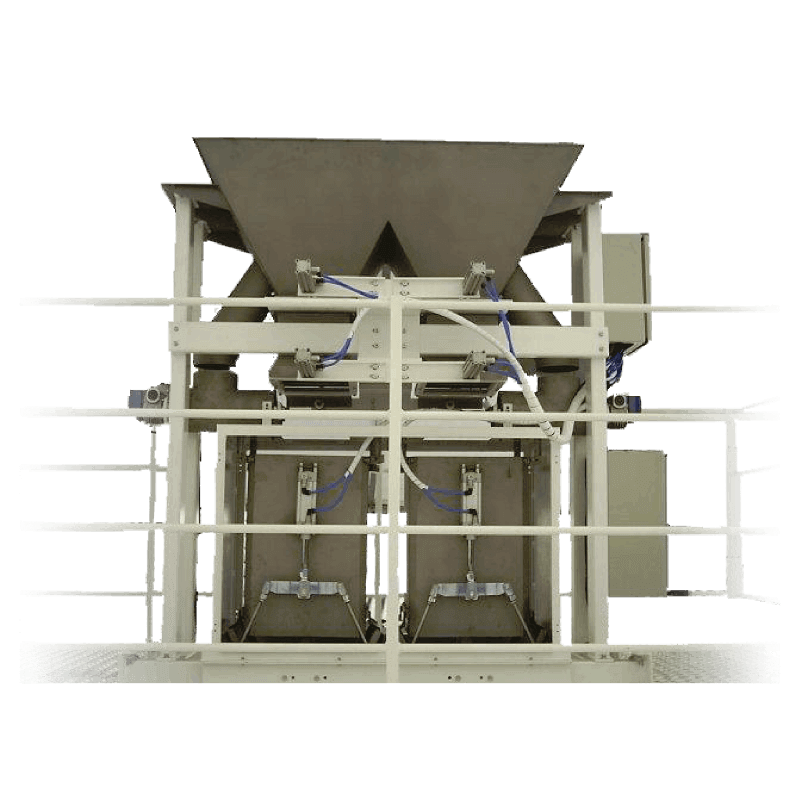

Fillers

Industries That Benefit from Automatic Packaging Machines

Automatic packaging machines serve a wide range of industries with excellence, providing solutions tailored to the characteristics of each product and the requirements of the sector:

Food

Hygiene & Cleaning

Chemical

Agribusiness

Animal Nutrition

Construction

Why Choose Indumak Automatic Packaging Machines?

At Indumak, your industry benefits from packaging equipment with cutting-edge technology, always focusing on efficiency, safety, and customization:

Equipment with quality certifications

Nationwide technical support with a trained team

Project customization according to your product and production line

Smart software for production monitoring and control

Indumak Automatic Packaging Machines in Action

By investing in a packaging machine, your industry achieves significant gains in performance, quality, and operational cost-efficiency:

Histórias de sucesso: como a Indumak auxilia indústrias a automatizar o empacotamento

Frequently Asked Questions About Industrial Packaging Machines

What is an automatic packaging machine and what is it used for?

An automatic packaging machine is a fully automated system used to package products on a large scale quickly, consistently, and efficiently.

It is essential in production lines for companies that need to ensure volume, quality, and speed in packaging.

Its use provides:

- Automation of the packaging process

- Increased production line productivity with continuous cycles

- Standardized packaging, ensuring a uniform and professional finish

- Reduction of waste and human errors

What Are the Main Types of Automatic Packaging Machines?

Vertical, mobile table, fixed table, continuous, and large-weight packaging machines.

Which automatic packaging machine is ideal for my type of product?

The choice of the ideal packaging machine depends on factors such as the product’s shape, weight, volume, and characteristics (solid, liquid, granular, powdered, etc.), as well as the type of packaging desired.

Our specialists carry out a technical analysis to recommend the most suitable model, whether vertical, mobile-table, fixed-table, continuous, or large-weight.

How much does an industrial automatic packaging machine cost?

The price will vary depending on the model, production capacity, level of automation, customizations, and optional accessories.

To provide an accurate quote, it is important to understand the specific needs of your operation.

What is the delivery and installation time?

The delivery time varies depending on the model and configuration chosen, but it is generally between 90 and 120 days after the order is confirmed.

Installation is carried out by our specializedtechnical team, ensuring the correct operation of the equipment and training for your staff.

Do you offer technical support and maintenance?

Yes, we provide specialized technical support, preventive and corrective maintenance, as well as remote assistance.

We have an on-site technical team and the necessary structure to ensure prompt service and continuity of your operations.

To contact our team, you can reach us through PRATI (Indumak Technical Assistance) at 0800 702 0550.

Is the packaging machine compatible with my current production line?

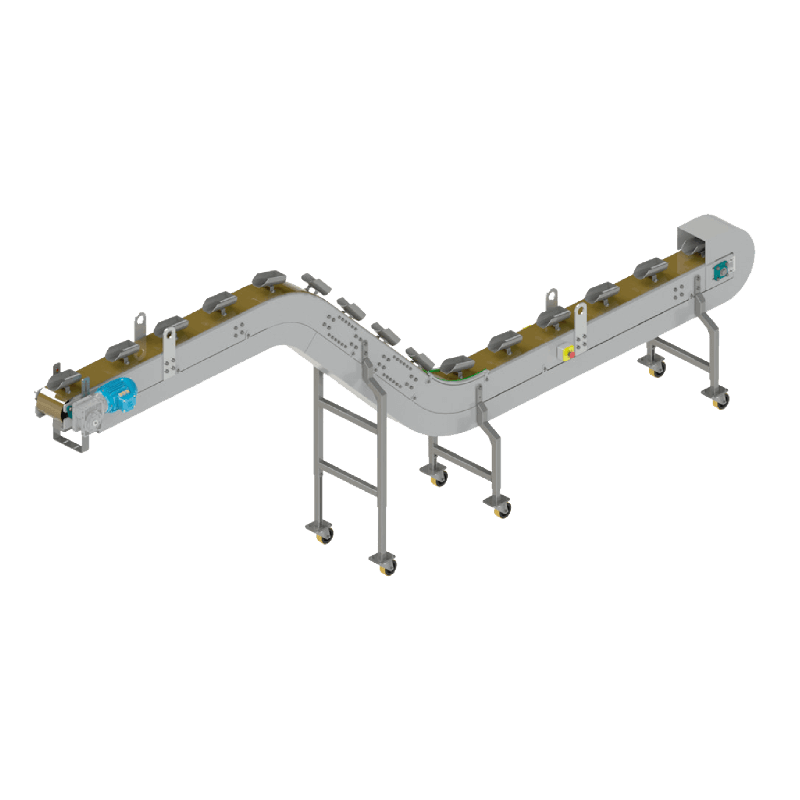

Our equipment is designed for easy integration with existing production lines, including feeding, conveying, filling, palletizing, and inspection systems.

We carry out technical studies to validate compatibility and propose any necessary adjustments.

Do you want to boost your productivity with cutting-edge technology?

Indumak solutions are designed for those seeking efficiency, standardization, and scalability in industrial processes.

Don’t suffer from reduced productivity. Rely on our technologies to enhance your industry’s competitiveness.

Request your quote now.

Other Indumak Equipment

Also explore our other solutions and achieve complete integration in your operation, from portioning to pallet wrapping.